O man, this is one of my jamb's!

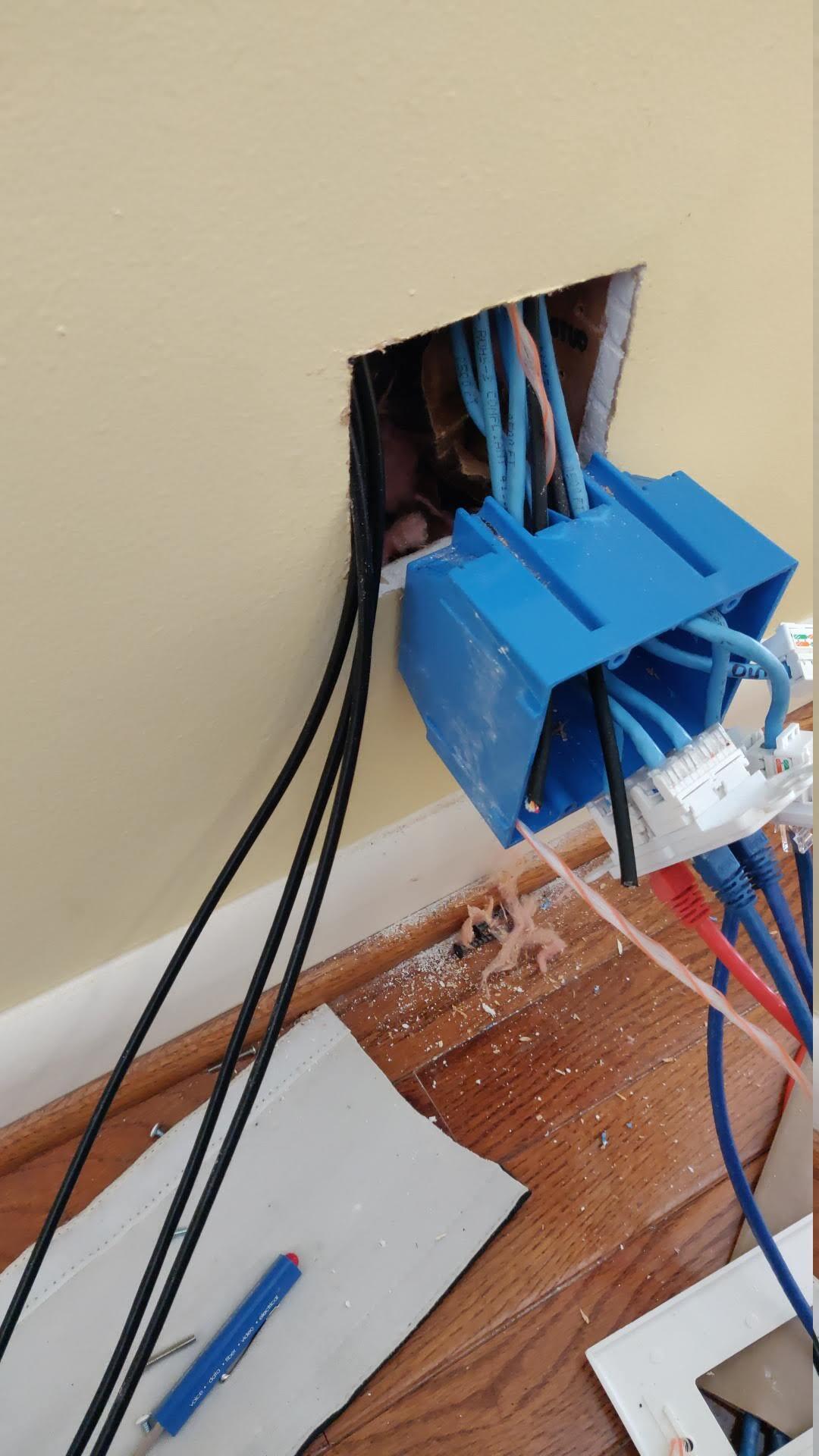

- Conduit: not required, you can run through walls with cable, but!!!! Any time I open up a wall for any reason I run conduit. I chose to run metal so I can run power in the future. Running "smurf tube" or PVC is perfectly ok for networking. The big advantage of conduit is that you can leave a pull string and/or fish new cables easily until its full

- YES!

- Sharpie before all other tools ALWAYS LABEL THE CABLE BEFORE YOU PULL IT. If you dont you will be testing later on with more expensive tools to figure out which cable is which. A Sharpie is cheep.

- Side cutters/cable cutters, or utility scissors (my recommendation) these are needed to cut cables, strip off jackets, and cut kevlar/thread or plastic core. https://www.bhphotovideo.com/c/product/1718739-REG/jonard_tools_es_1964_electrician_s_scissors.html

- RJ45 Crimp tool, you can do pass through ends or not thats up to you, but get good ones they are worth the investment. https://www.bhphotovideo.com/c/product/1043092-REG/eclipse_tools_902_354_network_tool_bundle.html

- Drywall Saw https://www.homedepot.com/p/Klein-Tools-6-in-Drywall-Saw-with-Plastic-Handle-725/100647777

- Fish tape or glass rods (I prefer fish tape) 25' or 50' are fine for home use.https://www.bhphotovideo.com/c/product/1718757-REG/jonard_tools_fts_50_steel_fish_tape.html

- Lightweight cordless drill, I like Milwaukee but there are plenty of options https://www.homedepot.com/p/M12-FUEL-12-Volt-Lithium-Ion-Brushless-Cordless-Hammer-Drill-and-Impact-Driver-Combo-Kit-w-2-Batteries-and-Bag-2-Tool-3497-22/320268525

- Heavy duty corded drill (hammer suggested) https://www.homedepot.com/p/DEWALT-7-8-Amp-Corded-1-2-in-Variable-Speed-Reversible-Hammer-Drill-DW511/100037000

- Paddle bits, get at least one long one so you can get through wall top-plates https://www.homedepot.com/p/Milwaukee-High-Speed-Wood-Spade-Bit-Set-13-Piece-48-27-1520/305537862 https://www.homedepot.com/p/Bosch-Daredevil-1-in-x-16-in-Spade-Bit-DLSB1013/203274545

- I also like wood boring bits https://www.lowes.com/pd/BLACK-DECKER-Marples-14-Piece-Woodboring-Drill-Bit/1003008984

- Pull string, every time you pull a drop, pull some string so you can run more lines in the future! https://www.homedepot.com/p/Gardner-Bender-1-8-in-x-6500-ft-L-210-lbs-Strength-Poly-Pull-Value-Blow-Line-in-a-Bucket-PL132B/313821648

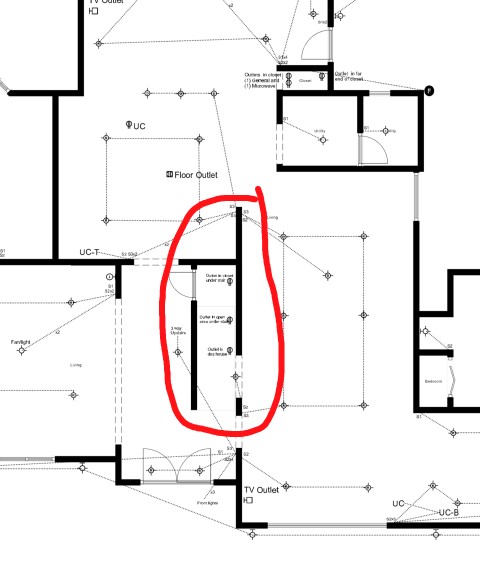

- Use interior walls as much as you can. Very often you can find closet walls and interior walls that have almost no electrical in them and have no insulation which makes running cable very easy. I would avoid exterior walls as drilling into the top plate near the roof line is a tight space and running fish tape with insulation is a pain in the butt.

Example of a decent interior wall that should go from basement to attic even on a multi story house.

Example of a decent interior wall that should go from basement to attic even on a multi story house.

I like to use low cost bike hooks to keep my cables off the ceiling in the attic that way im not walking all over them they are very affordable but are not great for long pulls as they drag on the cable jacket. https://www.homedepot.com/p/Everbilt-Vinyl-Coated-Steel-Screw-In-Bicycle-Hook-25-lbs-21407/206585761 real J Hooks that are designed for cable are $$$ https://www.homedepot.com/p/ICC-3-4-in-J-Hook-ICC-ICCMSJHK22/204517525.

I ended up installing 2x 3" PVC conduits from my basement rack through a closet wall into the attic. From there I run cable through the bike hooks until I get to the wall I need to do the drop in, and then I drill a hole in the wall top plate and drop my cables down that wall.

I always try to drop my cables along side a vertical stud so I will cut into the wall BEFORE i run cable and do so directly adjacent to the stud. I dont install the box until the cable is run, but I use the cheap new construction boxes https://www.homedepot.com/p/Carlon-1-Gang-18-cu-in-Blue-PVC-New-Work-Electrical-Switch-and-Outlet-Box-B118A/202546986 and just cut the nails off rather than use more expensive "old work" boxes https://www.homedepot.com/p/Carlon-14-cu-in-PVC-Old-Work-Electrical-Outlet-Box-1-Gang-B114RB/100404027

Some drywall screws in the side of the box going into the stud are more than enough to secure it.

When cutting the box in I find the stud (use a magnet, never trust a stud-finder) measure to the middle of any existing boxes or outlets. I then measure that hight out about about 1" from where I expect to find the stud, and I cut in the direction of the stud with my drywall saw. Once I hit the stud I pull out the saw, and I align the box center to the cut, and the edge to the vertical stud. I trace the outline of the box using a pencil and then cut along that line. If you do it this way it should end up level, the same height as other outlets/boxes, and be permanently secured so it wont fall out like some of the cheap low voltage cutin's that cable companies LOVE.