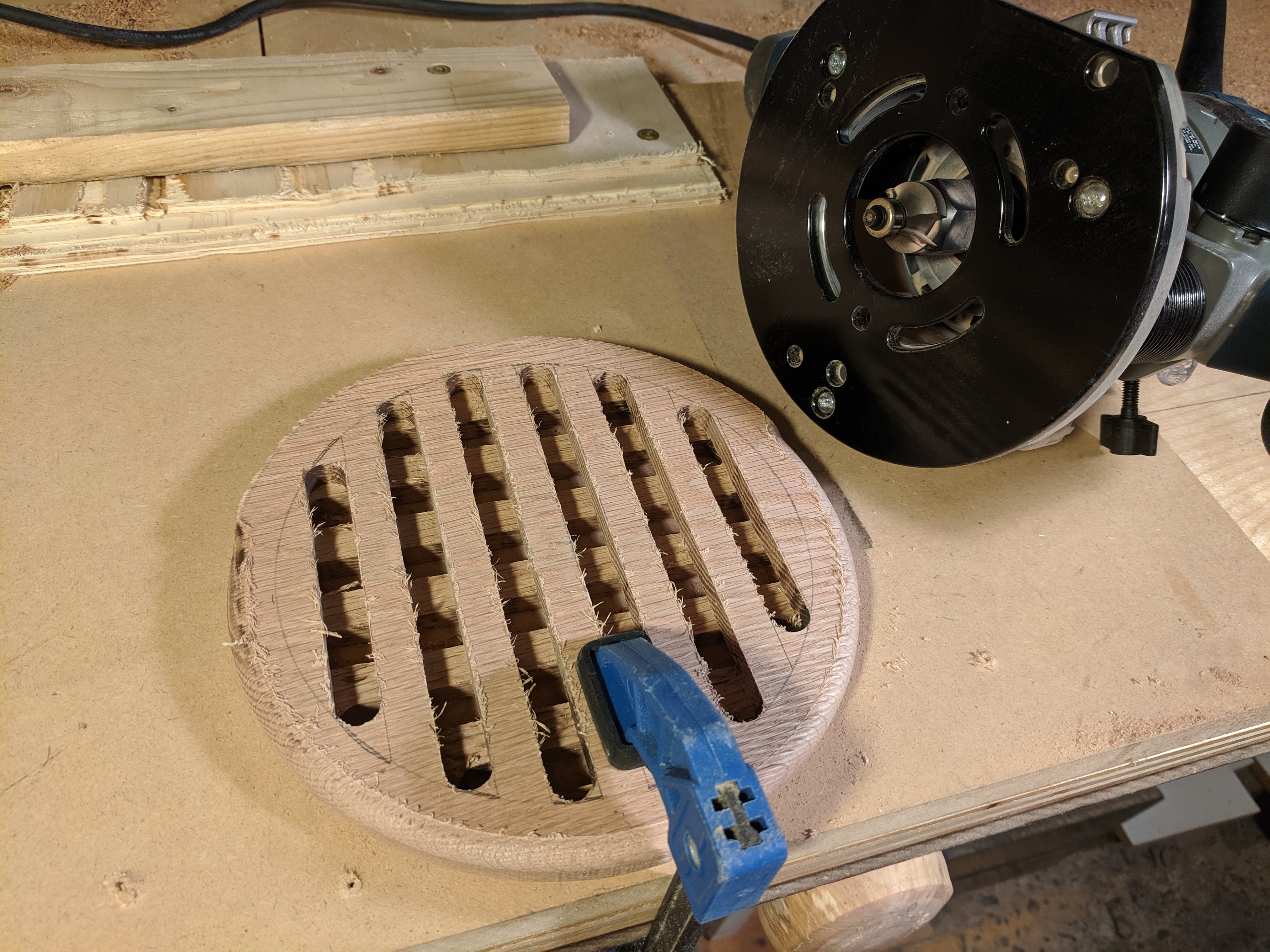

First router project. My family had a trivet like this when I was growing up, and I wanted to recreate it. Made from a scrap end of an oak board.

One of the channels on the bottom has a little deviation but otherwise they came out pretty much straight. And there's a fair amount of burning on the sides. I was moving very slowly at full depth, so I wouldn't have to try to get to the exact same endpoint multiple times at different depths. Curious if that's a likely source of burn and what a better way would be; it's not really a problem on the oak but would be on lighter wood (and I have an ash scrap waiting to be v2).

I started with a practice on a plywood scrap.

The jig mostly just holds it in place, with a fence along the back and 1", 2" and 3" spacers (then flip it around to work in from the other side).

For the real thing, I cut it out first on a bandsaw circle jig. That left a pinhole in the center, still slightly visible after a sawdust + glue patch, but it's on the bottom. Placing a channel in the center could avoid that.

After all the criss-cross cuts (routes?) I used a 1/4" roundover. The set of the bandsaw left the outside a little rough, so I'd probably smooth that out before doing the roundover next time.

Finally, 80 + 150 + 200 with the orbital sander (just holding the trivet in my hand to do the edge and rounded corner), and butcher block finish.

Casual DIY used a simple jig to make a cool pattern with overlapping curves, if not a spiral.

Fortress Fine Woodworking went full Spirograph. Maybe a less dense pattern like that on one side, and concentric circles on the other, would look cool?

In one of his videos on the Antikythera mechanism, Clickspring approximated a spiral as a series of offset circular arcs using a trammel and scorper. He makes soul achingly beautiful machining videos, go watch them.

I think I just invented a relatively simple router jig to lay out and cut a spiral/scroll. Imagine a circle cutting jig, but the router is held in a track. The pivot is anchored so it doesn't turn, and the arm/track circles around it. The router is pulled in/pushed out by an acme screw that runs through the pivot, and the nut it rides in is turned by a bevel gear from the pivot. So as you push the router around its orbit, that action turns the lead screw. That should get you a constant rate spiral, and you could adjust the pitch by adjusting the ratio of the bevel gears.

Or do the "wind a string around a drum" technique but I don't like the idea of doing that with a ROUTER.