VoronDesign

301 readers

1 users here now

lemmy.world community for VoronDesign 3D printers

founded 1 year ago

MODERATORS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

view more: next ›

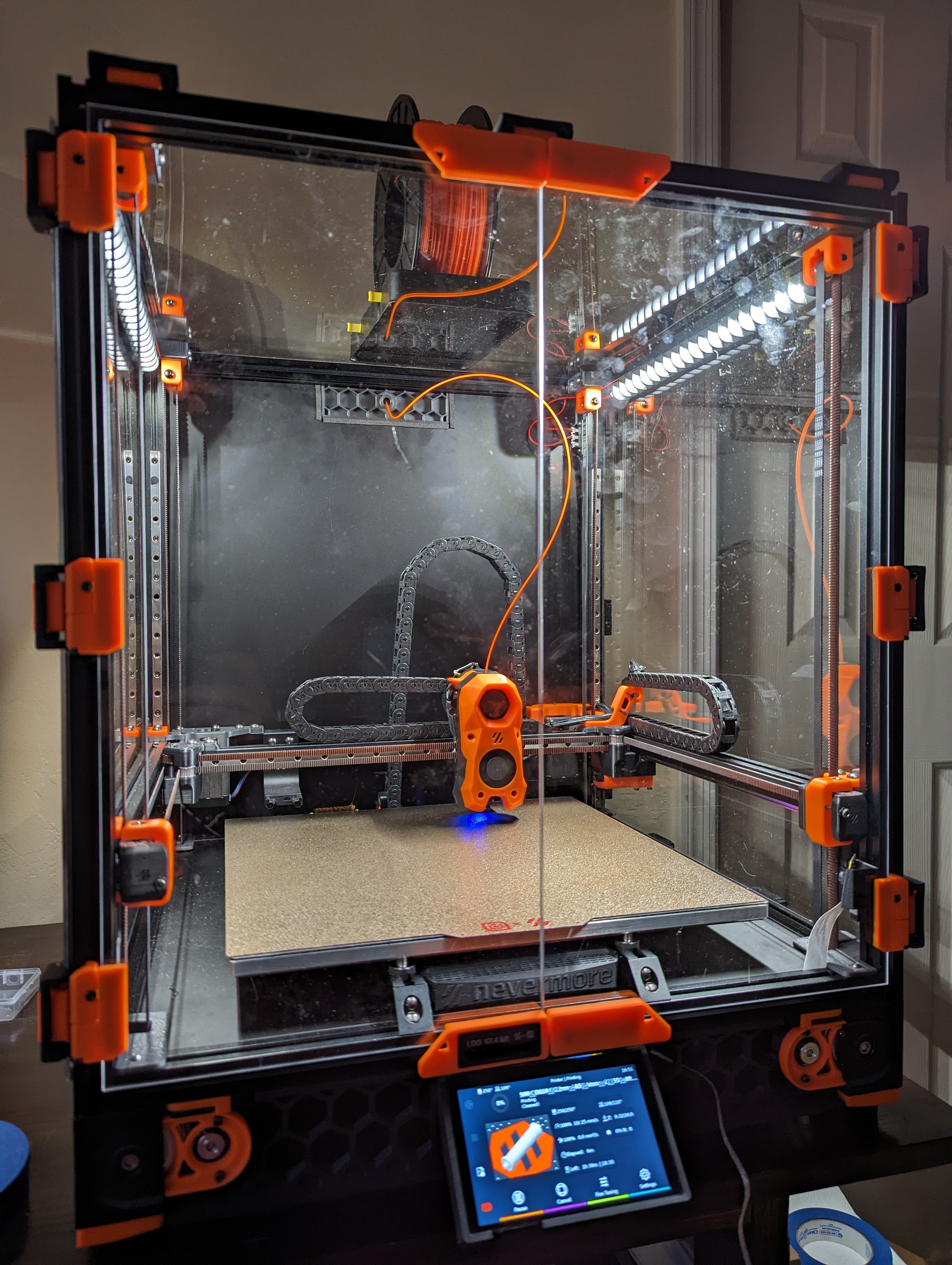

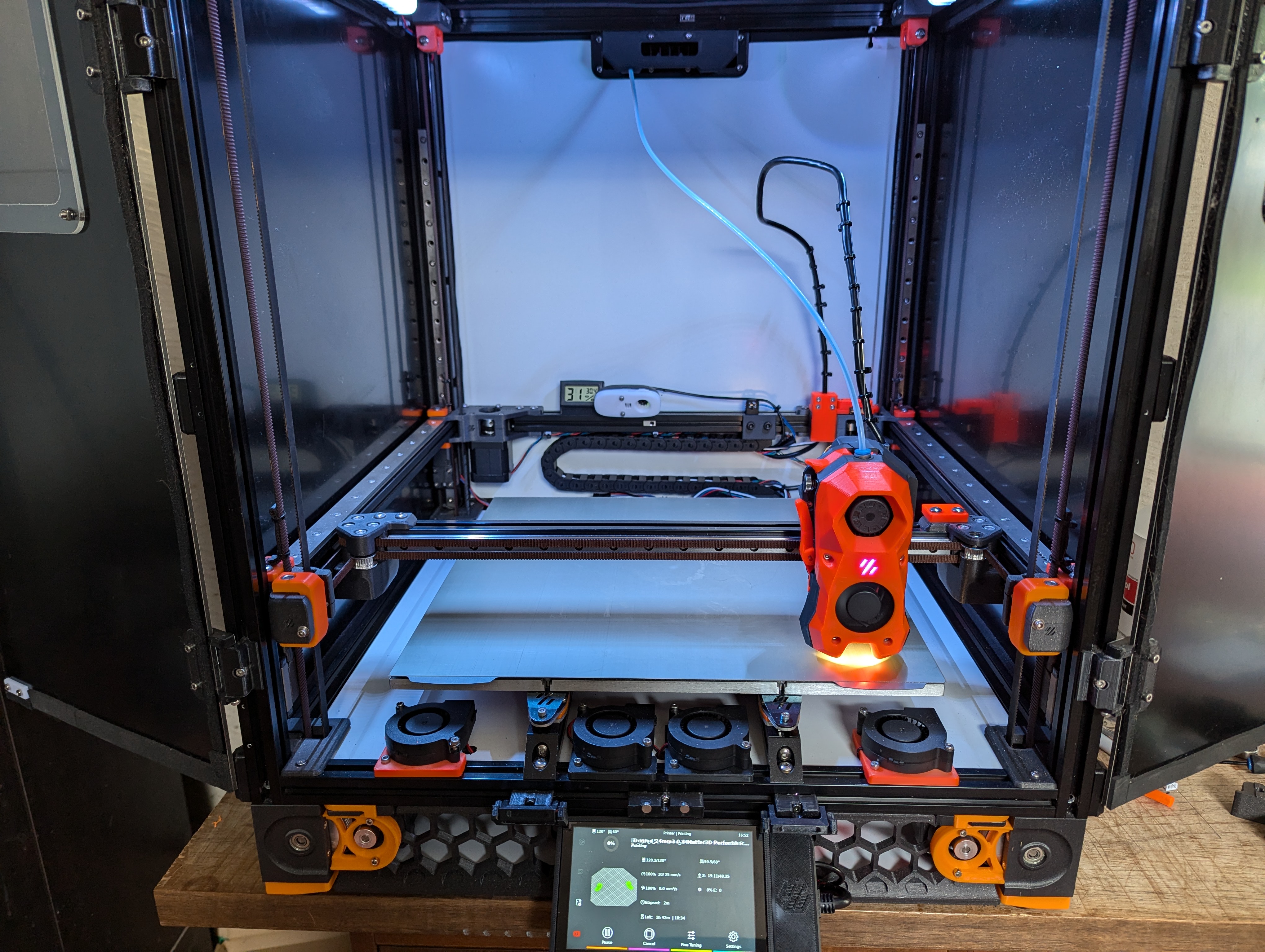

went for a usb can device over running can from the octopus pro, did want to swap the pro over to can as well but ended up keeping it the same instead of messing with reflashing firmware. Hotend has a little 3015 fan and a heatsink on the arm chip so cooling should be fine, looked up the datasheet and it's got a tjmax of like 120c and rated for ambient -40-80c so don't think I need to worry about it, if it's an issue I'll run a fresh air feed to it, will see how it likes abs in the summer shortly.

went for a usb can device over running can from the octopus pro, did want to swap the pro over to can as well but ended up keeping it the same instead of messing with reflashing firmware. Hotend has a little 3015 fan and a heatsink on the arm chip so cooling should be fine, looked up the datasheet and it's got a tjmax of like 120c and rated for ambient -40-80c so don't think I need to worry about it, if it's an issue I'll run a fresh air feed to it, will see how it likes abs in the summer shortly.