Is there any research about how this avoids air pockets?

I'm curious how the "liquid metal" achieves 'wet' contact compared to a compound that can be applied in a way that pushes out air as it is compressed.

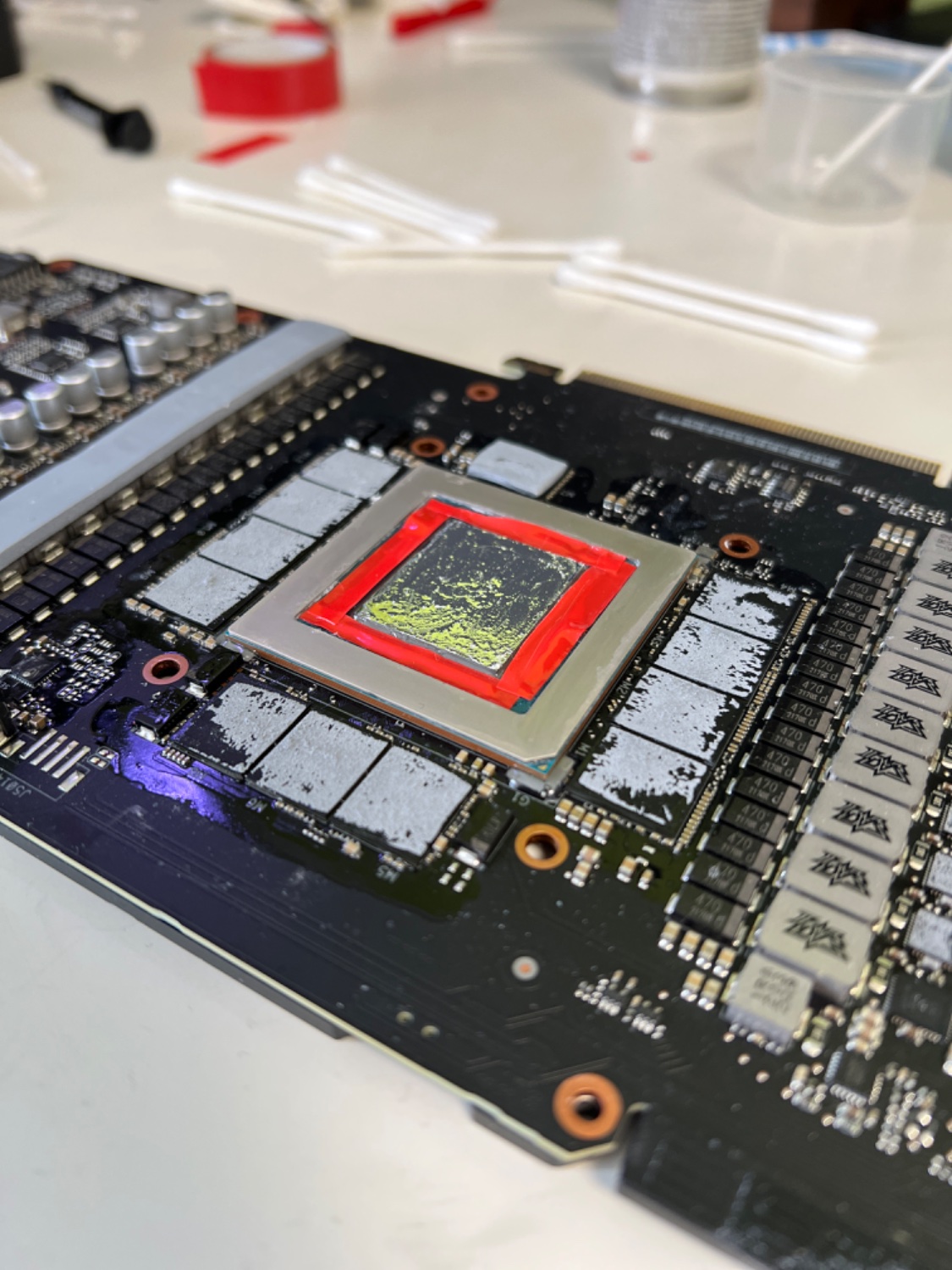

You are actually applying the thermal compound to the physical die. I don't know the structure on the silicon, and how they are integrating temperature management. Thermal contact consistency looks like it is super critical for this kind of package.

The only reference I found (in 5min of looking) about the die and packaging:

https://piped.video/watch?v=biEoBo8S0Zo

If anyone knows of content that goes deeper by removing the die and etching the layers with high resolution microscopy I would love to see this, or if anyone has deeper info about the "liquid metal" compound without any marketing nonsense, I'd like to see that too. I know Tech Ingredients on YT covered thermal compounds, but I don't recall anything about liquid metal.