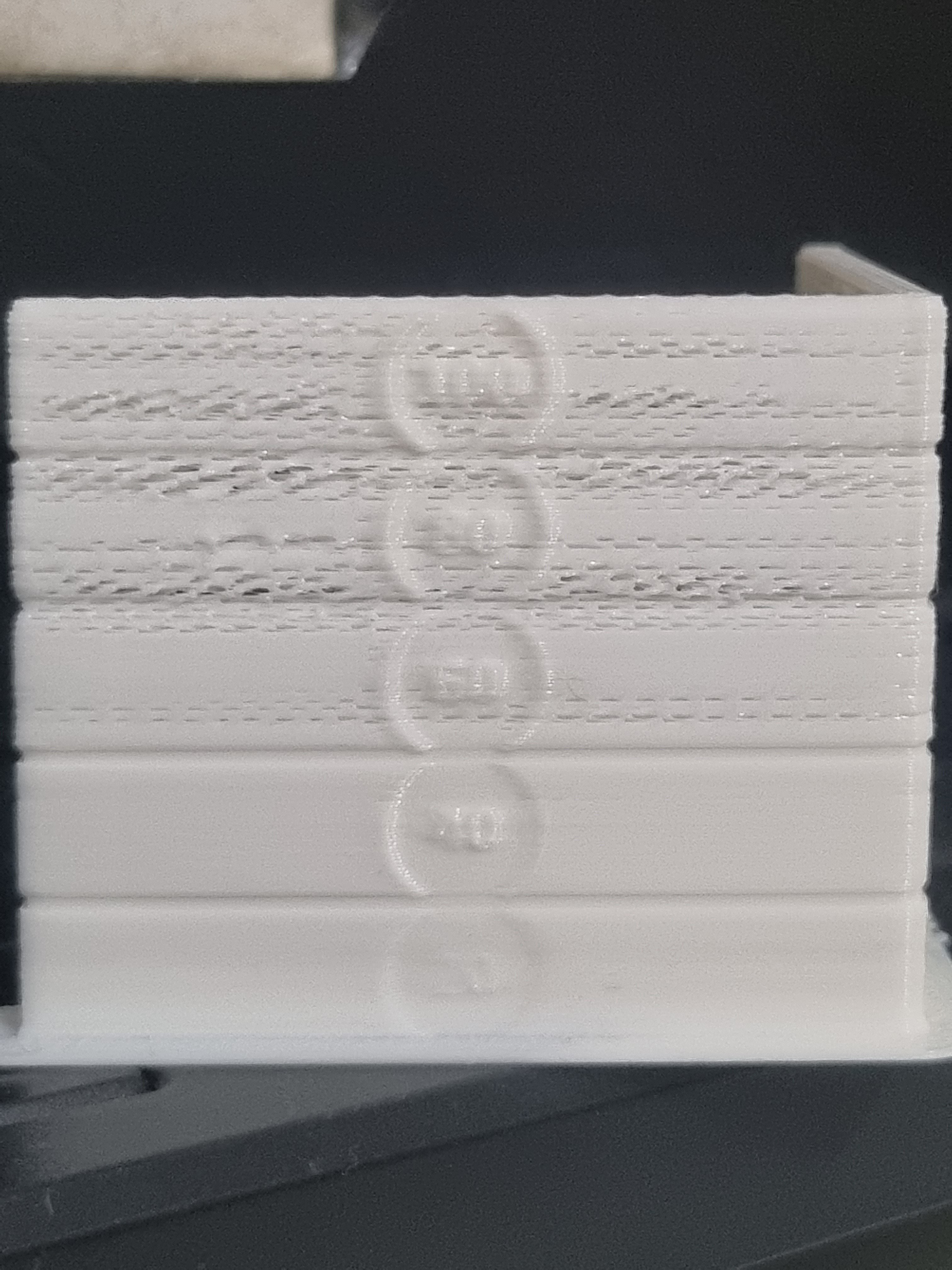

I see you just printed a bonchee.

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: [email protected] or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

The fact it won't print below 220° makes me think it's a problem with your hotend, and my best guess is that your nozzle is clogged. The higher temperature might be helping the extruder to squeeze a bit of filament around the clog, but not enough.

Changing the nozzle is quick and easy, and most printers come with a spare or two, so I would give that a shot before diving too deep into diagnostics.

They might just try a cold pull or two before changing the nozzle. (Depening on the printer. On my Ender 3 Nozzle swaps were a no brainer - 2 minutes, on my current SV08 they are 15 min of work and 45 min of soaking the old nozzle in Isopropanol to get the thermistor out without ripping the cables)

Wow I just looked it up and that is the worst design I've ever seen. That's a ton of work just to replace one of the most commonly changed parts.

My guesses are clog (99% of all extrusion problems), heater problem, wrong filament diameter or broken extruder (check for slipping and cracked arm, spring etc).

I don't know if twerking helps, but it doesn't hurt to try.

As long as you don’t twerk against the actual printer your should be fiiiiiiine.

Was the hot end pre-assembled or did you assemble it? I suspect you have a mechanical issue, but it might just be e-steps.

Suggestions:

Pull the nozzle off, measure say 110 mm of filament upstream of your extruder motor, make a line or attach a piece of tape, extruder 100mm, and see how close to 100mm you are. No nozzle means you can do this cold so you've eliminated 2 variables: a nozzle clog and temp. More detailed instructions

Once you get that sorted, do a PID tune and run the 100mm extrusion test again with your nozzle attached at say 230. Different number? My money would be on a partial nozzle clog.

Finally, temp tower. Not being able to extrude below 220 seems very weird. How fast are you trying to print?

What kind of printer is it?

I'm definitely not a printing expert but it looks like you're under extruding, is the extruder the same size as the old one or is there some other change like that? I say this because the bottom layers look better than the higher ones, from memory cura over extrudes for the first few layers to help with bed adhesion.

it is the same but I could try to change the flow

That looks like a clog.

Try heating up the end, then removing the filament, then cut the filament flush and push it into the end, lower the temp a bit, and yank it out. Do that a few times to try and clear the clog. You can also heat the end, remove the nozzle, and clean it.

While it's off, try pushing through some fresh filament by hand.

You were printing with wood, so it probably has wood particles stuck in it.

Changed the hot end? Like just the brass nozzle tip? Or the what?

Either way if pla isn’t printing below 220 I’d start with a pid autotune. This will let you see if the hot end is actually doing what it should.

This site:

https://teachingtechyt.github.io/calibration.html

Has all the steps for tuning a printer, pid and e steps are listed. It’s worked well for me on my old Ender3 Bowden drives and many of my newer direct drive ones.

What printer do you have?

oh thanks!!! I'm looking at the e steps and will look at pid after!

Do we have a cursed benchies community on Lemmy?

Try calibrating your E steps if you haven’t already. Hope this helps! https://3dprinterly.com/how-to-calibrate-your-extruder-e-steps-flow-rate/

Hey thanks!! This tip was gold and it helped A LOT

Make sure all of the parts of your hotend are tightened. Especially where the Teflon tube ends. I set up a new printer once and it was having similar issues and it ended up the nozzle wasn't fully tightened and was getting plugged up in the small gap. Changed the nozzle, cleaned the plugged material out, and made sure everything was tight, and it started printing just fine. Most PLA should print well at 200.

I had similar printing issues with some filaments, due to heat creep. The printing would start ok on mine, but after the printer had been running awhile it would print like that. In my case heat was travelling up the hot end and Bowden tube, which was causing printing issues after a certain amount of time had passed. Some filaments were more sensitive about this than others, my cheap plain filaments and my multicolor filaments wouldn't print well, but medium to high quality plain filaments would print fine.

There are a lot of things that can contribute to heat creep, I ended up replacing my hot end and Bowden tube, and lowered my print temperature some.

220° is pretty high, I would try to figure out why it won't print below that temperature and see what you can do to bring that down. See if that fixes it.

I'm using high quality filament. The low quality ones wouldn't even print lol

It really sounds like you have a major problem with the printer that needs to be resolved. Without knowing any more details I would suggest making sure the nozzle isn't clogged and possibly replacing the hot end.

It's a new hot end and new nozzle, that's why I pretty sure it can't be a clog or hotend problem. It was having this issues before and I changed the whole hotend for a brand new

Huh, possibly bad extruder? If it's got weak extrusion it might only be able to push it through the nozzle at higher temps.

I posted an update. It's very clear my printer has a problem I just can't figure it out. I will try to change the extruder but It seems to be working fine... anyway, I'll keep trying

What kind of printer is it? Do you maybe have a direct drive extruder while using Bowden style retraction settings?

Hey I just saw your update! I'm glad you're getting better results, but like you mentioned, something is definitely still wrong. I'm still pretty convinced your nozzle is clogged, even though it's new, and I'll do my best to explain why!

To start, if your printer wasn't working normally before you printed in wood, I'm totally wrong about everything below and you can stop reading here!

If your printer was working normally before you tried printing in wood though, that means the e-steps were already calibrated correctly, and they wouldn't need to be re-calibrated after replacing the hot end. If you had replaced the extruder and it started acting this way, that would be a good reason to re-calibrate the e-steps, but replacing the hot-end shouldn't have had an impact. After swapping an extruder, you calibrate e-steps to basically teach the printer how to extrude the correct amount of filament in the real world again since the new extruder might have different specs from the original and the printer has no way to know something has changed. A hot-end swap doesn't necessitate recalibrating e-steps though because the extruder is the same and it's still going to be pushing the same amount of filament through the printer.

If your nozzle is clogged and you recalibrate the e-steps, the measurements you take will be off since the printer can't push filament through at the rate it should be able to. Your new benchy looks better than before, but that could be because the higher e-steps you calculated mean the printer is now forcing more filament past the blockage by working the extruder more. It's been calibrated to compensate for the fact it can't push filament through fast enough, but it's working harder to do this and it will severely limit its speed before it starts underextruding again. I'm guessing this is the reason for the 3 hour long benchy at 20mm/s? You shouldn't need to be at 220 C to get PLA to print at 20mm/s from a 0.4mm nozzle either.

Not all nozzles or hotends are well-made or handled with care at the factory. It's totally possible you got one that shipped with some sort of tiny unnoticeable debris inside that worked its way down into the nozzle as the filament pushed it along. I have a cheap bag of 0.4mm nozzles that have metal shavings stuck in some of them and your first benchy is exactly what my prints look like when I use one of them. If possible, I still recommend changing the nozzle before doing anything more expensive like replacing the extruder. You'll probably need to set the e-steps back to what they were before changing them though, otherwise you'll be extruding too much filament if the new nozzle isn't clogged and the old one is.

Hey thanks for the tip. Indeed this printer never worked correctly, it always printed PLA with over 220c temp, but since printing wood forced me to change some things that melted I just decided to look more into it. The e-steps were probably wrong since the begining and I never new to calibrate it but now I have to understand why it only prints nice when at 20mm/s. But I'll look at clogs too, something could have been loose there from wood.

Oh one more thing, Temp towers never work in my printer It's like all the stages are the same temp, even checked the code., it never had a good temperature control, but I just changed the heating block so it must be something in the configuration that I don't know.

I printed the speed tower below (from 20mm/s to 100mm/s) and you can see it's only printing nice at 20mm/s