3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: [email protected] or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

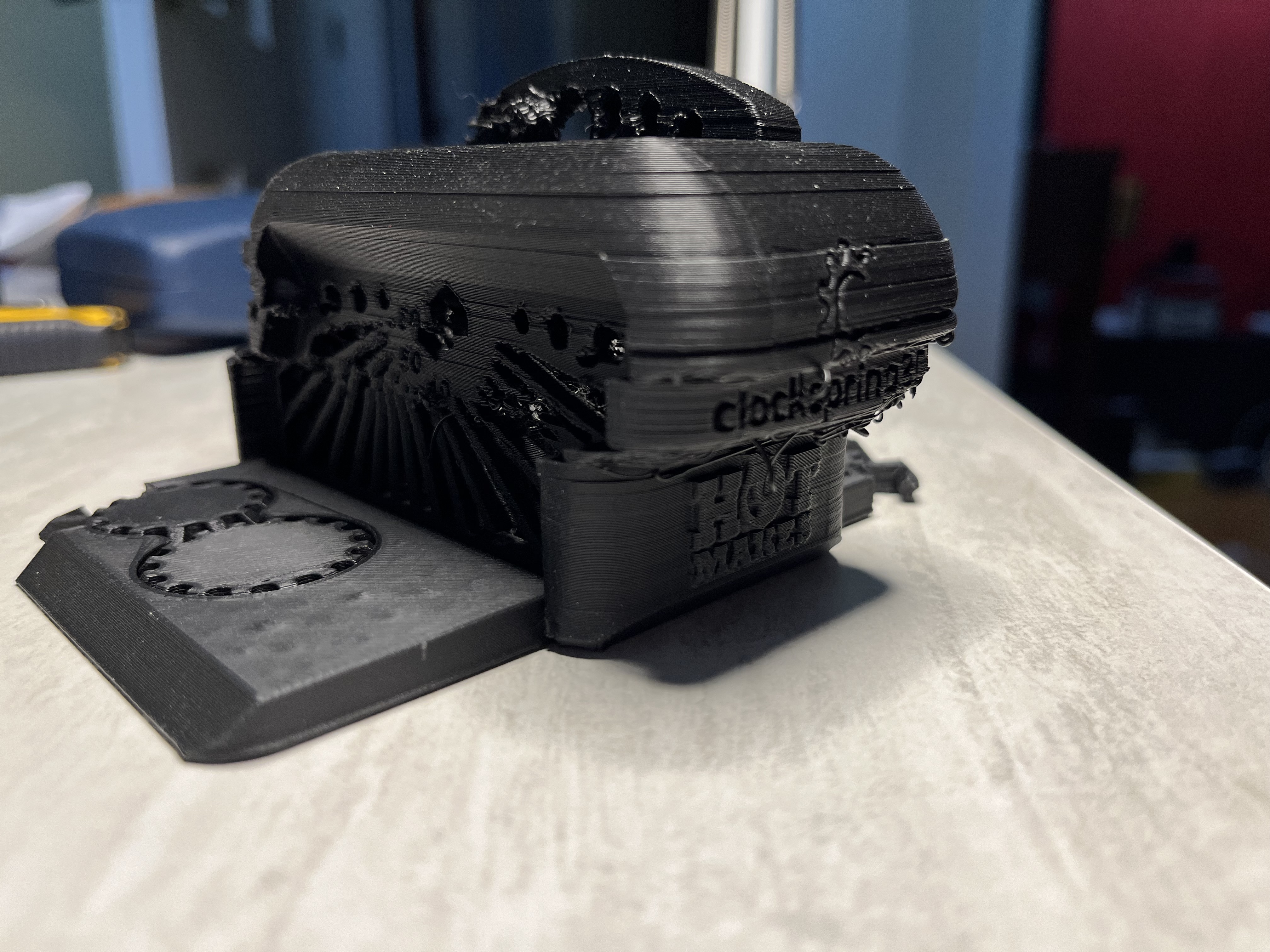

+1 to the skipped steps discussion. Those offsets are from the print head somehow getting stuck and not moving when the stepper driver commands a move. Reasons can vary but often they are mechanically related.

One very basic test is to move the head with your hands through its entire travel range on both axes (with motors off ie M84 or printer off) and feel the resistance to motion. Steppers of this size are not particularly powerful; you can overcome their force with your hands.

Another possibility is that the acceleration is set too high: a fast direction change puts a lot of force on the motor. Try setting your acceleration really low, like 100, in the slicer and see if it still behaves that way. If not then there’s your handle on a parameter to tune.

The poor behavior in the toast is probably a different parameter that needs tuning. I suggest getting the layer shift problem fixed before worrying about anything else.

I second this, but even small overextrusion can make bumps that cause collision with nozzle and therefore skipped steps. There are many other scenarios where you can have 0 issues with hardware and still failures like this. Id first start with simple models and make sure hardware is fine, then move on to more advanced models/tuning. Maybe OP just have bad slicer settings or it can be just low vref on stepper driver or lose belt pulley. But yeah, if axis doesnt move smooth dont look further, fix that first