Hi everyone, just to put some content in this community, I thought that sharing my setup could be useful to some people!

I have a Creality Ender 3-S1 Plus as my first printer. Why this choice? because... I wanted a big set, it suited my budget, and... I didn't know too much about it so I followed my instinct.

First thing I did was to replace the original firmware with this one. Many more features including a lot of work on the touch screen, and more compatibility with Octoprint (see below).

I then installed a led strip with a support printed by me.

Then Tasmota connected sockets (open source firmware).

Driven by Octoprint, I can turn on my printer remotely, then the LED strip and the printers will be turned off automatically at the end of printing.

Open-source was important to me, for control to be done locally only, and not via a server on the other side of the world..

I then discovered via Reddit (urg) the existence of Octoprint.

After trying to install it on my first generation RPi, I bought an RPi 4 and created myself an optimized server.

I added some plugins including:

- Bed visualizer: to have a 3D visual of the bedleveling

- OctoEverywhere! (in free version) to have access to my server outside my local network (at work for example)

- Signal Notifier: to send me a message on Signal (I hate Meta and therefore Whatsapp) when the print is finished

- Tasmota: to control my connected sockets, very easy to use by adding commands in my Gcode

- UI Customizer: to have a beautiful interface

- Slicer Thumbnails: to have a preview of the Gcode rather than just the name (requires manipulation in Cura)

- M73 progress: to display the printing progress on the touch screen

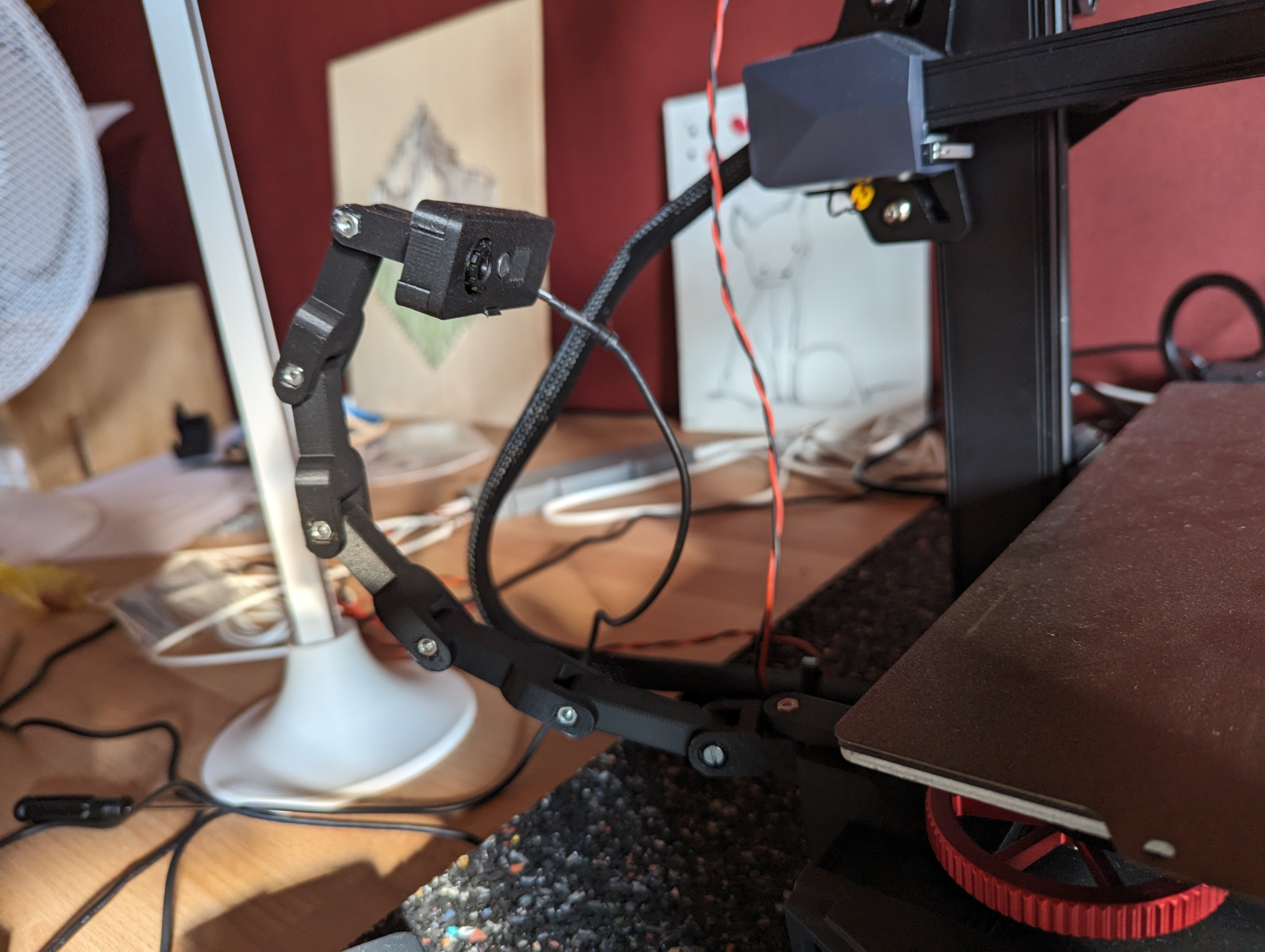

To perfect my installation and avoid going back and forth to check my impressions, I installed a Logitech HD C270 with a custom case.

Here, to conclude, I had a lot of trouble with Signal to install it on the RPi but I created a script to achieve this easily. And I burned my first bed by putting a Z-offset too low so I bought another one on amazon which I am very satisfied with.

My next project will be to confine my printer to print ABS.

Edit : (Yes, I need to clean the bed)

Edit 2 : Here's the video to not burn your bed, watch it until the end!